Our Process

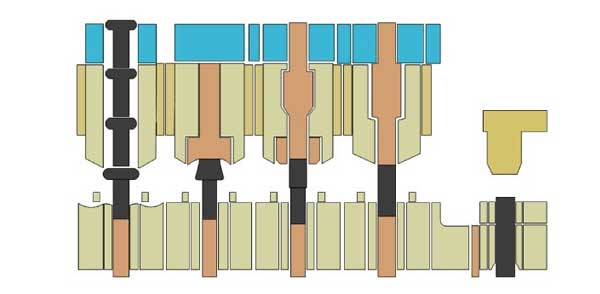

World class multi-station bolt formers enable us to manufacture complex shaped fasteners and components with high level of precision. Ranging from dia. M5-M16 mm. Length 10mm-140mm.

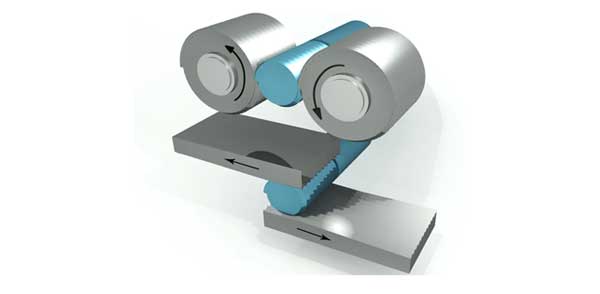

We are equipped with world class high speed rolling machines to produce uniform threads with closer tolerances and better size controls.

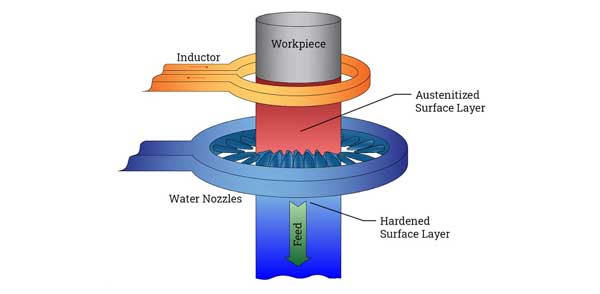

We have controlled heat furnaces and tempering furnaces to ensure cxceptional quality standards.

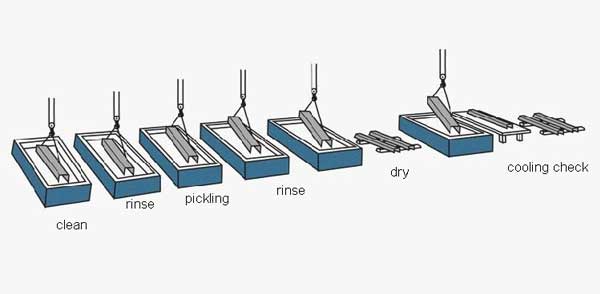

We provide different surface finishes such and Zinc Plating, Nickel, Zinc Iron, Geomet.

To Produce components with more intricate dimensions and critical dimensions we have a complete set up of CNC machines (make LMW), Turning Machines.

- Center-less Grinding

- Profile Turing

- Micro en-capsulation facility

Testing

We ensure best quality fasteners and automotive components with close tolerances and limits. We have In house testing facilities for the same.

- Brinell hardness Tester

- Rockwell Handness Tester

- Profile Projector

- Surface Roughness Tester

- Optical Microscopes for thread check